RESY RSF roll screen filter system

The RESY RSF roll screen filter system is used mainly as a standalone machine to remove chips from the filtering media. The filtration effect is varied by using different kind of filter fabrics.

The standard version is equipped with 80 µm plastic fabric. No additional filter materials are required and operation is fully automatic. In the inner drum, the filter fabric has been closely fitted and is, therefore, not subject to heavy strain. Consequently the lifetime of the fabric will take several years.

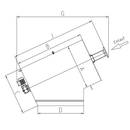

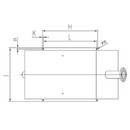

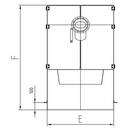

The filter consists of a continuously or intermittently rotating filter drum supported on bearings and inclined upwards at an angle of around 25° towards the discharge. Fitted inside the drum is a discharge screw, which rotates with the drum by means of frictional interlock.

As the chips are kept rolling during rotation, the fabric remains clean. Any material sticked to the fabric is removed by a blast of liquid which cleans the drum from the outside before starting the filtration phase.

The roll screen filter is designed specially for cleaning liquids with high chip content without additional energy or operating material costs. With maintenance work reduced to a minimum, this system offers unsurpassed value for money.

For special processing requirements a dual-circuit system should be used. The RSF filter can be used for coarse cleaning. Media cleaned in this way can be used without problem to rinse tools and the external coolant for example.

For fine (10 to 20 µm) filtration – e.g. for internal lubricant supply – a KBF filter should be installed additionally in the bypass. This filter combination should be sufficient to meet all requirements.

| RSF 401/V | RSF 601/V | RSF 801/V | |

|---|---|---|---|

| A | 580 | 780 | 980 |

| B | 827 | 1157 | 1497 |

| C | 530 | 725 | 895 |

| D | 460 | 730 | 1005 |

| E | 520 | 720 | 920 |

| F | ca. 835 | ca. 1150 | ca. 1450 |

| G | ca. 1275 | ca.1620 | ca. 2010 |

| H | 500 | 775 | 1050 |

| I | 620 | 820 | 1020 |

| J | 1088 | 1465 | 1855 |

| K | 20 | 20 | 20 |

| L | 460 | 735 | 1010 |

| DN | 80 PN16 | 100 PN16 | 125 PN16 |