Rotary screen filter RESY RSF and RESY Duo

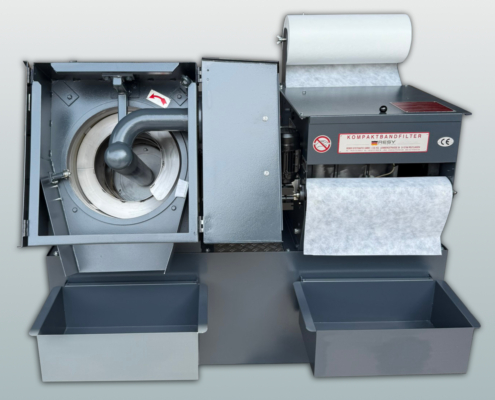

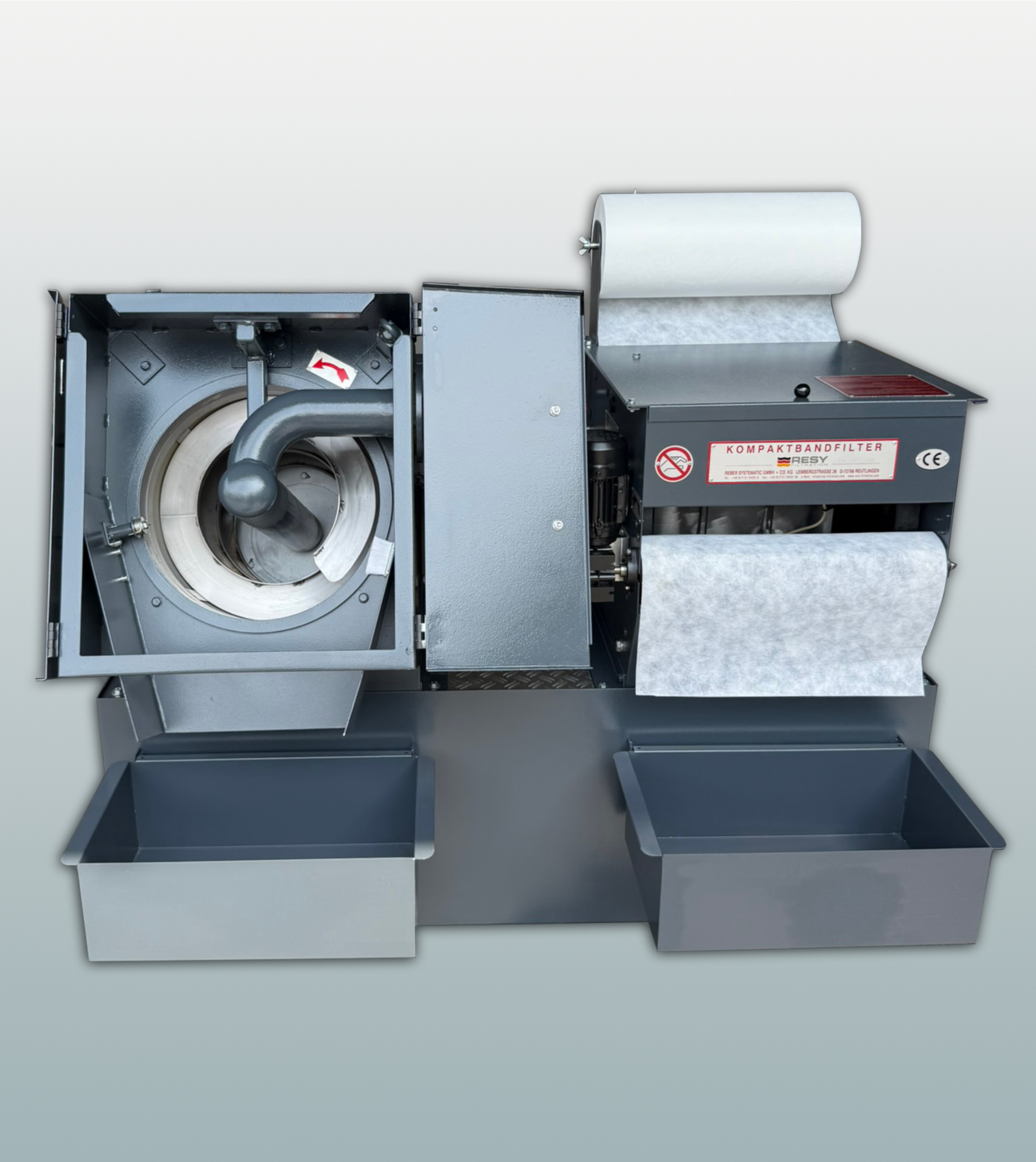

RESY RSF rolling screen filter system

The RESY RSF roller screen filter system is mainly used for chip disposal and medium filtration on individual machines. The filtration effect can be varied to a limited extent by using different filter fabrics.

The standard version uses an 80 µm chrome-nickel steel fabric. No filter aids are required. The filter operates fully automatically. As the filter fabric is fixed inside the filter drum and is therefore not subject to any stress, the service life of the filter fabric is several years.

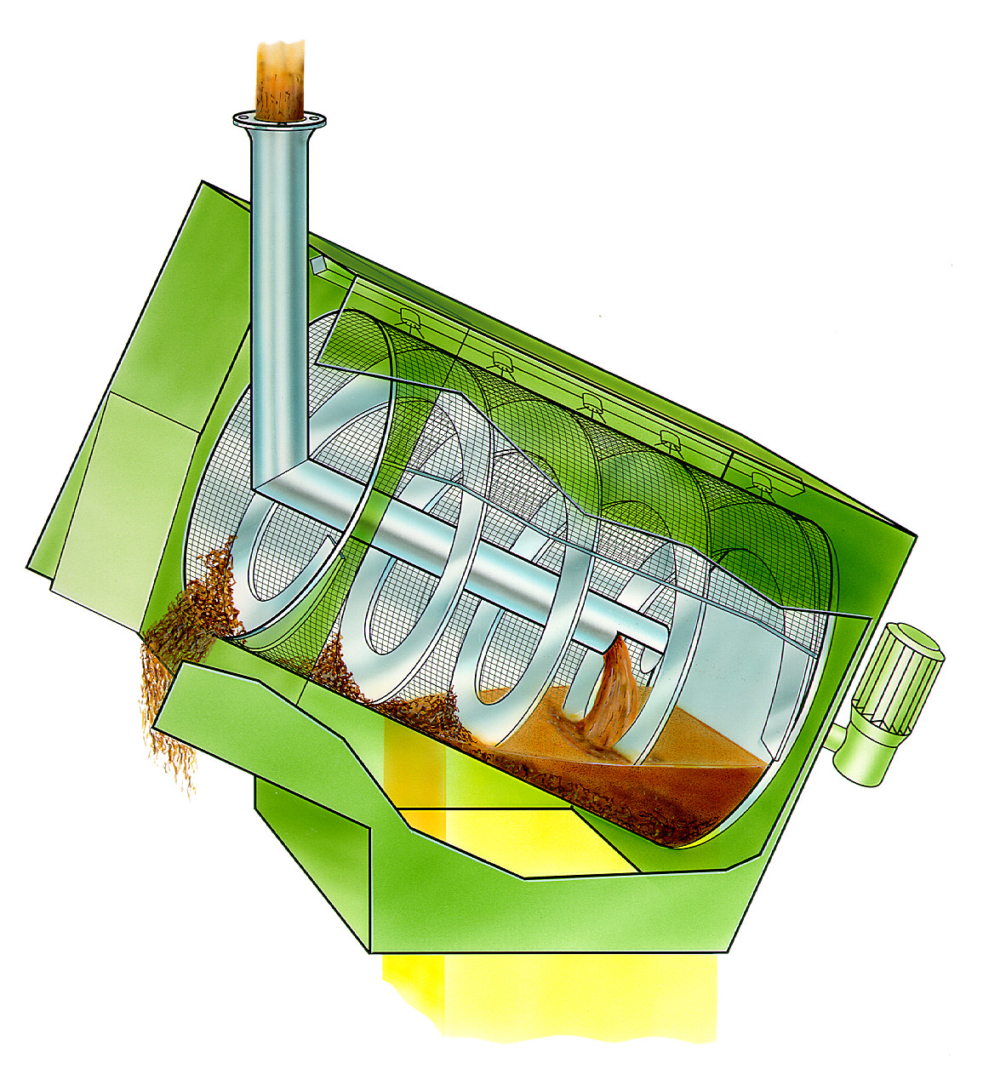

The filter consists of a continuously or intermittently rotating filter drum, which is mounted at an angle of approx. 25° rising towards the discharge. A discharge screw is integrated into the filter drum, which rotates with it in a force-fit manner.

The chips roll around during rotation, keeping the fabric clean. If internal adhesions or clogging do occur, they are removed by a nozzle block that jets the drum from the outside inwards before it enters the filtration phase.

The roller screen filter is a cleaning system that has been specially developed for cleaning large quantities of liquid with a high chip content. It enables cleaning without additional energy costs and without incurring operating costs. Maintenance is minimal. The price/performance ratio of the roller screen filter is unrivalled.

A two-circuit system must be used for special machining processes. This is recommended for coarse cleaning of the RSF filters. The medium cleaned in this way can be used without any problems for rinsing tools and for external coolant supply.

For fine cleaning with approx. 20 to 10 µm, for example for internal coolant supply, a KBF filter must also be installed in the bypass. This filter combination opens up a whole range of possibilities.

RESY RSF roller screen filter Operating principle

Principle

The RESY RSF roller screen filter has a lower throughput capacity than the RESY TF drum filter. It is mainly used for chip disposal and medium filtration on individual machines. The filtration effect is equivalent to that of the TF filter and can be varied to a limited extent by using different filter fabrics. The standard equipment uses an 80 µm chrome-nickel steel fabric. No filter aids are required. The filter operates fully automatically.

The filter consists of a continuously or intermittently rotating filter drum, which is mounted at an angle of approx. 25° rising towards the discharge. A discharge screw is integrated into the filter drum, which rotates with it in a force-fit manner. Depending on the chip shape or medium, the discharge can be fed directly into a container or into a centrifuge for drying.

The chips roll around during rotation, keeping the fabric clean. If internal adhesions or clogging do occur, these are removed by a nozzle block that jets the drum from the outside inwards before it enters the filtration phase. The roller screen filter is a cleaning system that has been specially developed for cleaning large quantities of liquid with a high chip content. It enables cleaning without additional energy costs and without incurring operating costs. Maintenance is minimal. The price/performance ratio of the roller screen filter is unrivalled.

A dual-circuit system must be used for special types of processing. This is recommended for rough cleaning of RSF filters. The medium cleaned in this way can be used without any problems for rinsing tools and for external coolant supply. For fine cleaning approx. 20 – 10 µm, for example for internal coolant supply, a KBF filter must also be installed in the bypass. – See Figure 2 on the right. This filter combination opens up a whole range of possibilities.

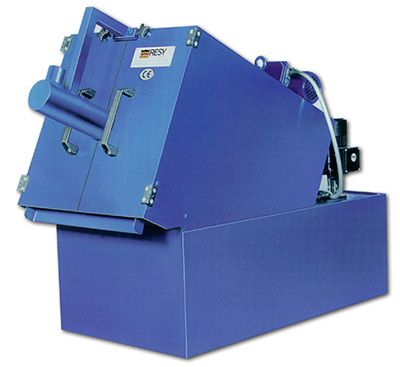

For compact applications with low throughputs, we also offer this product as a RESY Duo solution in combination with a KBF filter.

Technical specifications

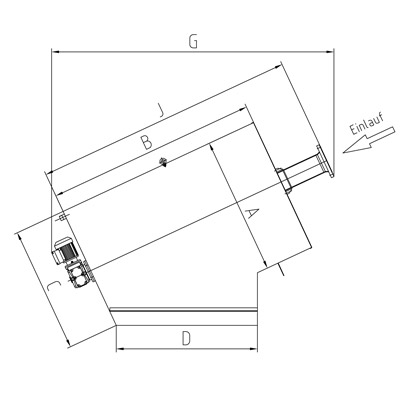

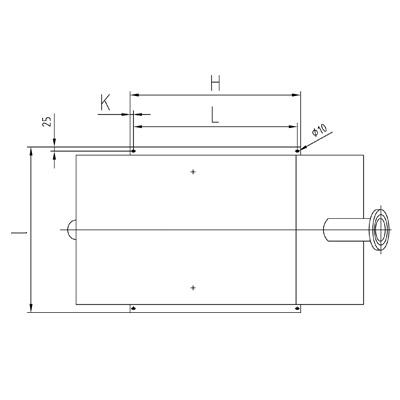

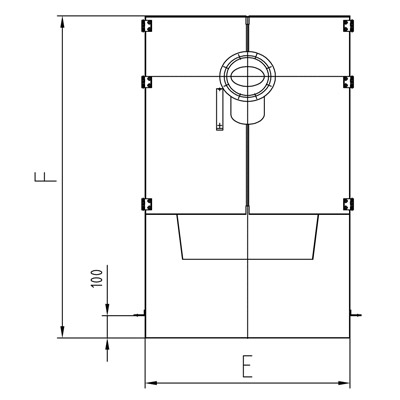

| RSF 401/V | |

|---|---|

| A | 580 |

| B | 827 |

| C | 530 |

| D | 460 |

| E | 520 |

| F | ca. 835 |

| G | ca. 1275 |

| H | 500 |

| I | 620 |

| J | 1088 |

| K | 20 |

| L | 460 |

| DN | 80 PN16 |