RESY KBF 803

World-wide the most flexible filtration system -

Fully automatic filtration over filter paper

Because of the possibility of using different types of filter papers, the desired effects can be achieved.

The filtration procedure takes place in a semi-circular shaped basin, with hydrostatic pressure of about 350 mm. Two disc wheels form the lateral sealing of the filtration basin. There are several waste removers between the disc wheels, which push out all the dirt. The filter inlet is centric. The outlet occurs throughout the whole area in a vertical downward direction. Dirty paper take up and filter cake stripper for separation of paper and waste are optional.

The given filtration efficiencies are to be seen only as a guide. Actual requirements of filter specification are calculated after taking into consideration all provided data. Of importance are:

Throughput, medium, filtration fineness, input of concentration, material and type of waste particles.

Please contact us for further details about your operation.

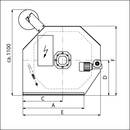

| KBF 803/710 | KBF 803/1040 | |

|---|---|---|

| A | 807 | 807 |

| B | 816 | 1134 |

| C | 519 | 519 |

| D | 460 | 460 |

| E | 1015 | 1015 |

| F | 900 | 900 |

| G | DN 100 | DN 100 |

| H | 716 | 1034 |

| Paper (mm) | 710 | 1040 |

| KW | 0,12 | 0,12 |

| Q=l/min | max. 500 | max. 750 |