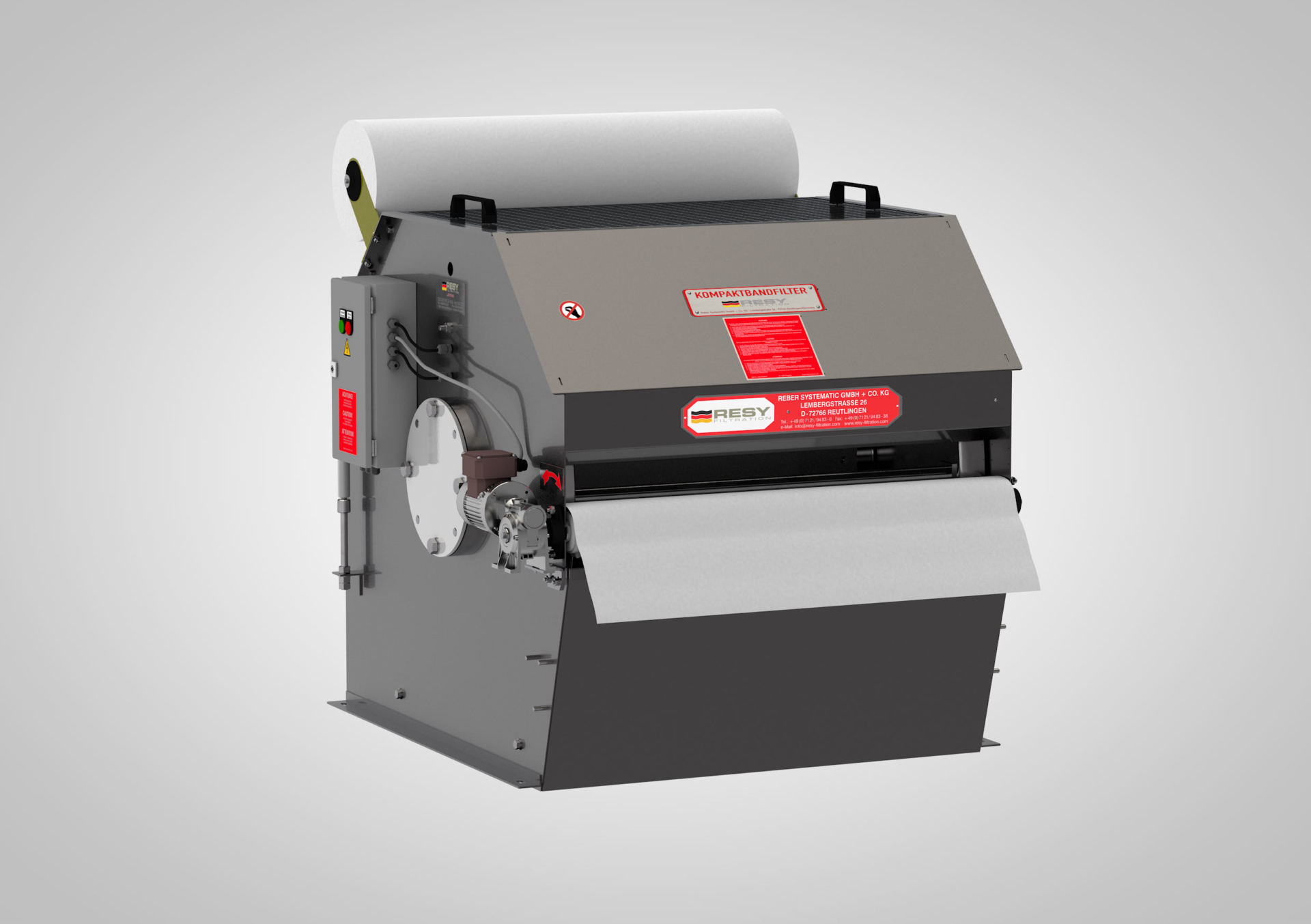

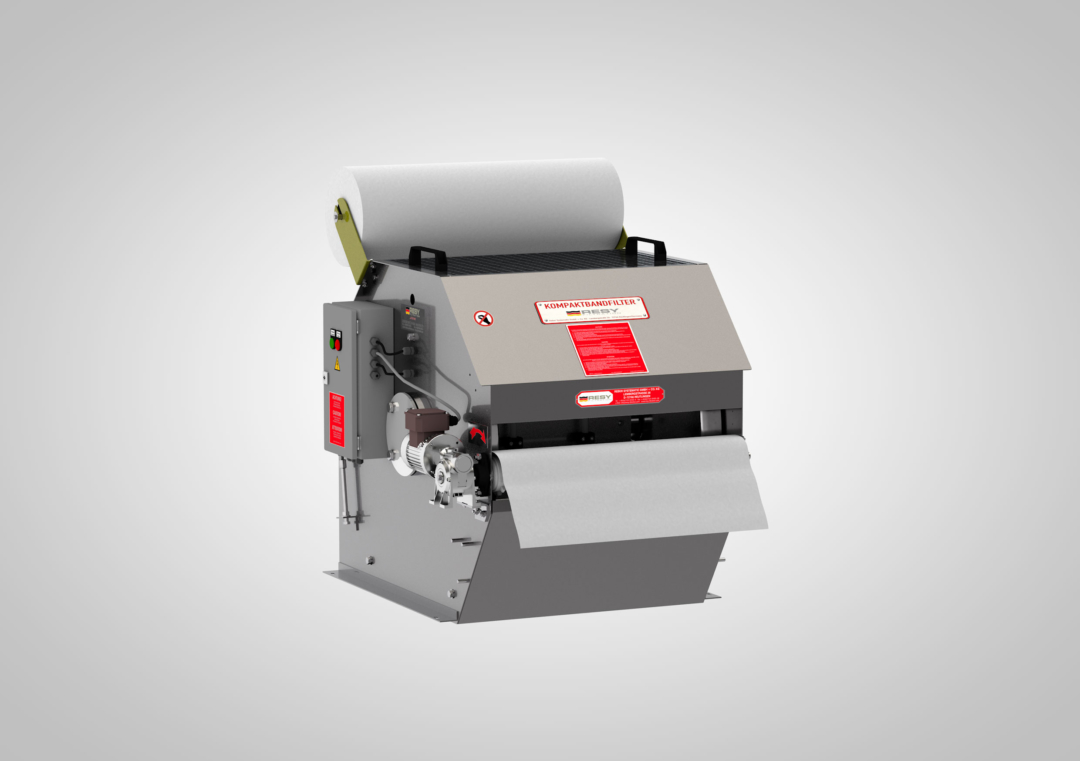

RESY Compact belt filter KBF

The world’s most flexible filtration system – fully automatic filtration using filter fleece or special fabric

The filter purity level can be individually adapted to customer requirements thanks to the option of using different filter papers.

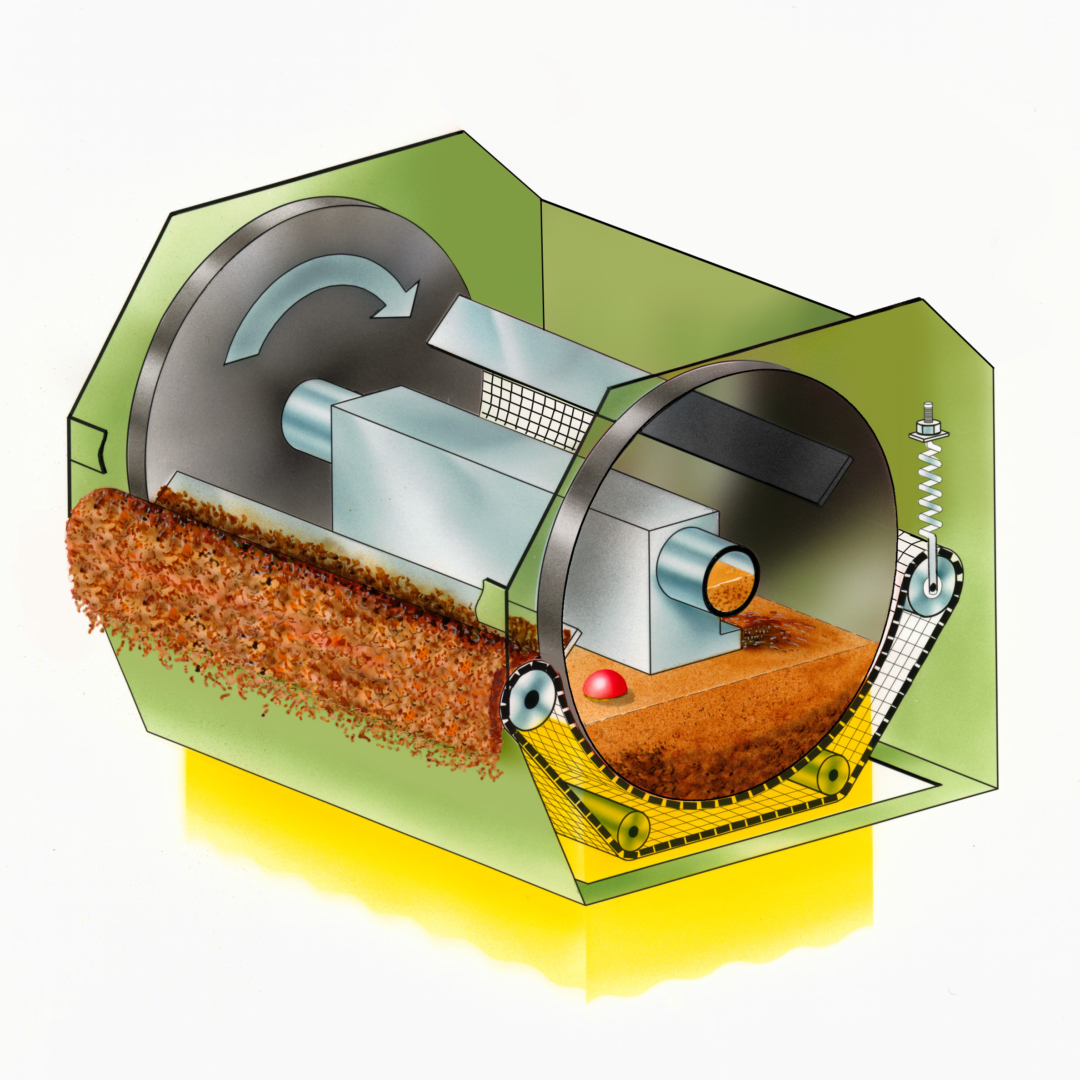

Filtration takes place in a semicircular filtration tank with a hydrostatic pressure of approx. 200 mm – 500 mm. Two filter wheels seal the sides of the filtration tank. Several sludge carriers are attached between the pair of wheels to eject all dirt. The filter inlet is centred. The filtrate outlet is located vertically downwards across the entire filter surface. Paper reels and filter cake scrapers for separating paper and sludge are available as options.

The specified filtration capacity is only to be regarded as an average value. The final design of the filter is carried out by us after all the relevant information has been taken into account. The following factors are decisive: throughput, medium, filter fineness, inlet concentration, material and shape of the particles to be separated, etc.

RESY KBF operating principle

The RESY KBF compact belt filter system is a pioneering development in belt filter technology. This unique filter has no relative movement between the conveyor belt, filter fleece, wheels and sludge carriers. This means that even large quantities of dirt and chips do not damage the filter fleece. With the same filter performance and a higher degree of purity, the space required for this filter has been reduced by up to 80% compared to a flat bed filter.

Principle

An endless, stable metal link belt is tensioned in a half-shell shape against two rotating disc wheels. The link belt is driven by a gear motor via a drive shaft. The filter fleece is inserted between the tensioned belt and the wheels. The filtration tank is sealed on all sides. The medium to be filtered is fed into the filtration tank through the centrally mounted filter inlet pipe. In small units, this central inlet ensures that the medium to be cleaned can be fed directly into the filter from the machine. This means that no transfer pump is required.

The particles then settle in the calming zone of the filtration tank and form the filter cake. This filter cake is also used as a filter layer and contributes significantly to an optimised filtration effect. As particle deposits on the fleece increase, a liquid level slowly but steadily forms in the filter.

Depending on the filter type, the level can be up to 500 mm. This high hydrostatic pressure enables optimum use of the fleece. When a maximum adjustable level is reached in the filtration tank, the gear motor switches on and transports new fleece without interrupting filtration.

The level in the filtration tank drops and the belt transport switches off. During this process, the filtered sludge and dirt particles are discharged together with the used fleece on the side opposite the feed. For processing larger quantities of sludge, chips and particles, individual carriers, similar to shovels, are attached between the disc wheels. They easily eject all sludge and coarse chips without damaging the filter fleece. The entire filtration process is fully automatic. A special sensor constantly monitors the diameter of the fleece roll and, when the roll diameter reaches a minimum, indicates that the roll needs to be changed.

The desired degree of fineness can be easily adjusted by using different types of filter fleece. For special applications, we also offer this product with endless belt fabric as a filter medium for applications with defined separation efficiency and materials. RESY KBF-E

RESY KBF 452

RESY KBF 803

RESY KBF 1001

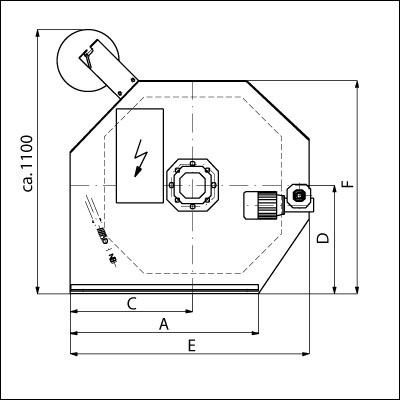

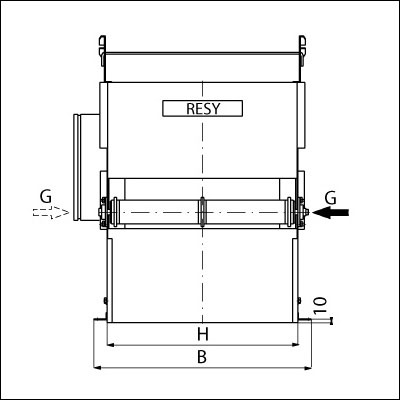

Technical specifications

| KBF 452/500 | KBF 452/710 | |

|---|---|---|

| A | 580 | 580 |

| B | 604 | 814 |

| C | 340 | 340 |

| D | 300 | 300 |

| E | 665 | 665 |

| F | 552 | 552 |

| G | DN 65 | DN 65 |

| H | 504 | 714 |

| Paper (mm) | 500 | 710 |

| KW | 0,09 | 0,09 |

| Q=l/min | max. 175 | max. 250 |

Technical view

The principle of filtration

USING THE EXAMPLE OF A RESY KBF FILTER

The RESY KBF compact belt filter system is a pioneering development in belt filter technology. This unique filter has no relative movement between the conveyor belt, filter fleece, wheels and sludge carriers. This means that even large quantities of dirt and chips do not damage the filter fleece. With the same filter performance and a higher degree of purity, the space required for this filter has been reduced by up to 80% compared to a flat bed filter.